Curing is the final step in the nearly 70-step, highly complex process of concrete production and placement. As in any process, missing or poorly performing any step can negatively impact the outcome (i.e., finished concrete) in terms of appearance and sustainability.

In part one of this series, we discussed the critical role proper concrete curing practices play in the longevity and performance of exterior concrete. In part two, we focused on parameters that affect curing such as, given our geographical location, cold-weather construction. In this third and final article of our series, we explore methods—as outlined by the results of a recent Minnesota Concrete Council (MCC) study—for achieving the best results possible from late-season placement of exterior concrete.

Freezicles and Call Backs

In our first part of this series, Terry Swor and Gerard Moulzolf described the winter of 2013-2014 as “brutal to exterior concrete performance.” To properly understand this characterization, it is important to compare the environmental conditions in the Twin Cities during this time (3.5 inches of precipitation) to the most recent winter (2014-2015), which experienced only 1.9 inches of precipitation.

However, the amount of precipitation alone is not what causes a winter to wreak havoc on early-age concrete; the combination of the amount of precipitation and the number of freeze-thaw cycles is what determines if marginal concrete and concrete placement/curing practices will be able to resist scaling. When a precipitation event proceeds a freeze-thaw cycle, AET affectionately calls it a “freezicle.”

Freezicles cause water to move in the concrete matrix from where it cannot freeze—in the small gel and capillary pores—to where it can freeze, such as in air voids and larger capillaries. This movement of moisture causes internal hydraulic and osmotic pressures that may result in scaling. Concrete that has the proper water/cementitious ratio, air-void system, finishing, and, last but not least, proper curing, will have the best chance of resisting the detrimental effects of freezicles. (AET’s second article extolled the benefits of even a minimal duration (i.e., four days) of wet cure in improving both the scaling resistance and freeze-thaw durability of late-placement exterior concrete.)

To continue our comparison of the last two winters in the Twin Cities: Winter #1 (2013-2014) experienced 24 freezicles, while winter #2 (2014-2015) experienced only seven freezicles. A less scientific but possibly more accurate quantification of the severity of the two winters is a measure of owner dissatisfaction, which is evidenced by the number of requests AET receives to identify the cause(s) of concrete distress. We call these requests “call backs.” Between the dates of April 1 and June 16, 2014, AET performed 173 call backs. Conversely, we have yet to be involved in any call backs for exterior concrete that was placed late in 2014.

MCC Laboratory Study

Many of the call backs experienced during the spring of 2014 were late-season placements of 2013. In response to the inordinate number of call backs, the MCC undertook a study titled “Scaling of Late Season Concrete Placements.” The goal of the study: to explore methods that could optimize the scaling resistance of exterior concrete during a late-season placement.

The study consisted of a 23 factorial statistical design laboratory phase and a 15 yd3 field placement phase. It considered these three independent variables:

1. Curing time

2. Type of sealer

3. Deicer exposure

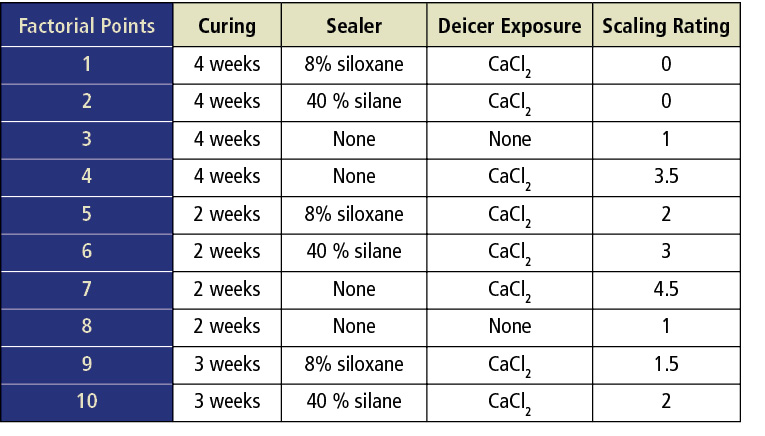

All laboratory specimens had a curing interval comprised of an initial water cure for 50% of the time followed by an air cure for the second half before being subjected to a freezicle. Some specimens, as shown in the table below, were given a four-week curing interval before being subjected to a freezicle, whereas others were given two- and three-week curing intervals. Thus, all specimens were subjected to better-than-average curing environments for late-season placement of exterior concrete.

The dependent variable (response) was scaling, which was determined in the laboratory by ASTM C672 “Standard Test Method for Scaling Resistance of Concrete Surfaces Exposed to Deicing Chemicals.” The test, by its very nature, is aggressive—it is designed to characterize scaling of exterior concrete during a normal service life.

The table below gives a summary of the study’s design and results.

The scaling response of the laboratory specimens was rated as follows:

0 – no scaling

1 – very slight scaling (3 mm depth, no coarse aggregate visible)

2 – slight to moderate scaling

3 – moderate scaling (some coarse aggregate visible)

4 – moderate to severe scaling

5 – severe scaling (coarse aggregate visible over entire surface), as shown by the photograph to the right

Responses to each of the ten factorial points can be seen in the last column of the table above (scaling rating).

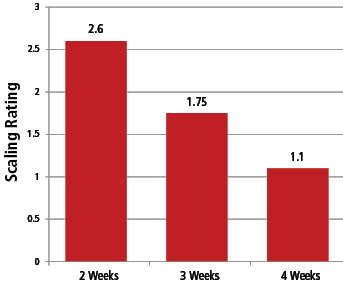

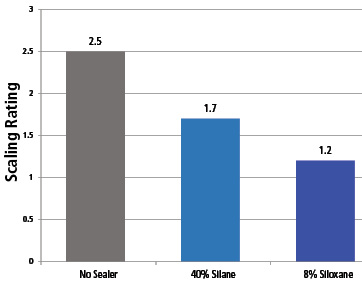

The following two graphs illustrate the average of the scaling responses of the samples, based on curing interval and sealer application.

Curing

The graph the to left shows that concrete that has been allowed to cure for four weeks before it is subjected to freezicles experiences significantly less scaling than concrete that was given only two weeks of cure time.

Sealers

The effectiveness of early application of penetrating sealers can be seen in the graph below. The use of 8% siloxane resulted in the concrete with the lowest scaling rating (i.e., the highest resistance to scaling).

However, it should be noted that the MCC study prepared the laboratory test specimens with an optimal curing environment before subjecting the specimens to the scaling test. This curing regimen rarely happens in the practical world of late-season exterior slab placements. As such, if specimens with and without penetrating sealers had been tested without receiving the water curing, it is likely all of the specimens would have resulted in higher scaling ratings. Moreover, the performance results should not be viewed as an endorsement of the siloxane penetrating sealers over those comprised of silane. We have seen other studies find the opposite results, although both penetrating sealers were shown to improve the performance of concrete.

Summary

The significance of the MCC study for AET’s “Consider the Cure” series relates to the practicalities of modern scheduling, which does not always give priority to proper curing. Exterior concrete slabs are particularly vulnerable as late-season placements given that the slab surface area is so large in comparison to the thickness or mass of the concrete. As we discussed in part two of this curing series, cold weather puts early age concrete at risk. Therefore, it is imperative to plan—and to implement adequate cold-weather protection and curing.

Nevertheless, a heuristic approach that prescribes a consistent curing plan for late-season placement will not always work. As the comparison of the weather data for the past two winters revealed, it is often Mother Nature that determines whether or not a curing plan can be implemented. The MCC study provides substantiation for the recommendation provided by Dr. Peter Taylor for late-season concrete placements: If water curing is not possible due to weather, consider using a penetrating sealer to improve the performance of exterior concrete!

We trust the information in this three-part series will help you to consider the cure.

Part One of this series can be found here

Part Two can be found here

Dan Vruno, a Principal Engineer in our concrete materials laboratory, can be reached at dvruno@teamAET.com