- Home

- /

- Services

- /

- Laboratories

- /

- Petrography

Petrography

Petrographic Analysis, Evaluation, Consulting

Our Petrographers use microscopes to better understand the construction materials used in concrete mixes, mortar, and similar products. The information helps prevent problems from happening down the road or helps figure out the cause of existing problems.

Our internationally-recognized Petrography Group evaluates samples of rock, aggregate, sand, concrete, mortar, and other cement-based construction materials to provide quality assurance and to troubleshoot issues.

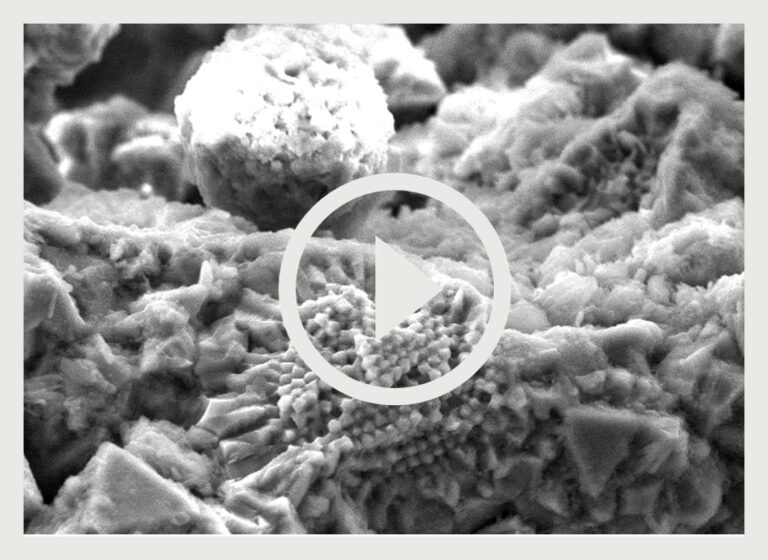

Our petrographic lab space is equipped with sophisticated stereo, petrographic, and scanning electron microscopes that let us examine the optical properties of materials and evaluate their microstructural characteristics. Sample analysis can also include a host of techniques, including use of Fourier Transform Infrared Spectrometry (FTIR), X-ray Fluorescence (XRF), and X-ray diffraction (XRD) to identify the components of various construction materials and admixtures.

We provide a detailed report, along with high-quality images and practical recommendations for solving an issue or construction challenge.

Petrographic analysis of concrete helps our clients make informed decisions

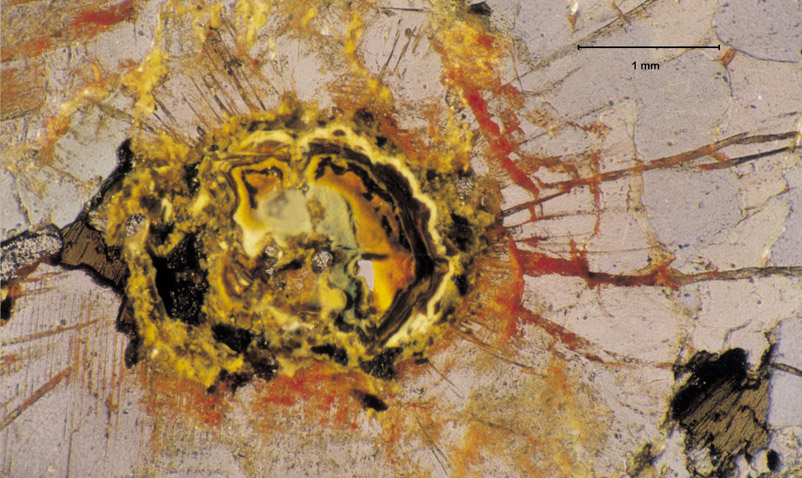

Petrographic examination lets us verify that concrete was mixed as designed; used the correct materials; and was placed, finished, and cured as specified. Using forensic techniques and observations we can also characterize concrete deterioration and defects, determine the degree of damage present, and evaluate whether the deterioration will continue.

Our petrography reports include an estimate of remaining useful life of the material and, where feasible, recommend options for extending that lifespan or repairing the material. This helps our clients make informed repair or replace decisions.

Petrography, by itself, can answer a lot of questions but sometimes we need other types of testing to fully address an issue. When needed, we collaborate with other AET labs, such as our certified independent asphalt, concrete materials and chemistry laboratories, to provide additional testing that will help identify constituents or validate pavement materials and a variety of admixture and chemical products.

AET provides independent petrographic evaluations

The AET Petrographic Group, which is located in St Paul, Minnesota, is not affiliated with any material or product supplier. We provide independent testing and analysis and unbiased evaluations of your materials. We are AASHTO accredited and U.S. Army Corps of Engineers validated in almost all test procedures.

We are proud to have one of the largest and most qualified petrographic analysis teams in the world. Our internationally renowned team of Petrographers are Professional Geologists with extensive experience. Our rock and sand testing services have contributed to successful projects for vertical construction, roadway, rail and transit systems, agricultural and industrial projects, and product development.

We understand the importance of anticipating the goals and lifespan of materials, managing your risk and adhering to project deadlines. The AET Petrography Group is the preferred provider for a wide variety of clients, including building owners, general contractors, project managers, and engineers, as well as material suppliers and manufacturers.

Petrographic sample collection for petrographic analysis

Every forensic project is unique, but each one begins with the collection of samples for us to analyze, along with relevant photos of damaged or defective areas.

Frequently, samples (broken pieces or cores) are collected by our clients and shipped to AET for evaluation. Our in-house Forensic Engineering team is also available for travel to your site to collect samples. Upon returning to the lab, samples are prepared, mounted and polished for evaluation.

AET has conducted forensic analysis to understand defects and failures with the following materials.

- Concrete

- Block and Brick

- Rock

- Aggregate

- Cement

- Pozzolans

- Grout

- Mortar (modern and historic)

- Tile and terrazzo

- Dimension stone and cladding

- Interior plaster and stucco

- Flooring/coating systems

- Lightweight concrete

- Swimming pool plasters and finishes

- Gunite and shotcrete

- Cement-stabilized soils

- Lime-stabilized base materials

Depending on the situation, our analysis of your samples can include a host of optical, chemical and crystallographic techniques. Petrographic analysis for concrete materials, for example, begins with accepting an aggregate for use in concrete (ASTM C295). Once the concrete is hardened, petrographic examination (ASTM C856 and ASTM C457) verifies the product was mixed as designed and that the right materials were used.

The AET Petrography Group evaluates building material issues

There is a wide range of problems that your concrete and masonry structures may experience, including but not limited to:

- Alkali-carbonate reaction (ACR)

- Alkali-silica reaction (ASR)

- Attack by sulfates and other chemicals, including salts

- Cracking

- Delamination

- Fire damage

- Freeze-thaw damage

- Water damage

- Discoloration and staining

- Low strength

- Popouts

- Scaling or spalling

- New and historic mortar evaluations

- Replication of historic mortars, stuccos and concretes

- Comparing hardened concrete to known mix designs

Specific Testing Capabilities of our Petrography Group

AET routinely provides these tests. We conduct many additional tests not on this list — contact our representative above to discuss your project needs.

- ASTM C295 Petrographic Examination of Aggregates for Concrete

- ASTM C457 Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete

- ASTM C856 or AASHTO T 277 Petrographic Examination of Hardened Concrete

- ASTM C1202 Rapid Chloride Ion Permeability

- ASTM C1324 Examination and Analysis of Hardened Masonry Mortar

- ASTM C1721 Petrographic Examination of Dimension Stone

- ASTM C1723 Scanning Electron Microscopy (SEM) with Energy Dispersive X-Ray Analysis (EDX)

- ASTM C1760 Bulk Electrical Conductivity of Hardened Concrete

- ASTM D4992 Evaluation of Rock to be Used for Erosion Control

- ASTM D5312 Evaluation of Durability of Rock for Erosion Control Under Freezing and Thawing Conditions

- ASTM D5313 Evaluation of Durability of Rock for Erosion Control Under Wetting and Drying Conditions

- ASTM D6473 Absorption and specific gravity of Rock for Erosion Control

- CRD-C 144 Standard Test Method for Resistance of Rock to Freezing and Thawing Conditions

- CRD-C 169 Standard Test Method for Resistance of Rock to Wetting and Drying Conditions

Contact a Laboratory Professional

Related Services

Laboratory Projects